A4P Four-Point Probe Automated Resistivity Mapping System

The A4P-Series Wafer Resistivity Mappers use proven industry standards to provide fast, accurate and reliable measurements of sample resistivity distribution. MicroXact’s four-point probes measure the average resistance of semiconductor wafers of layers by passing current through the outside points of a four-point probe and measuring the voltage across the inside points. The value of resistivity, the property of the material giving it electrical resistance, can then be found by multiplying sheet resistance by the thickness of a film.

Offered as a 100mm, 150mm, 200mm, or 300mm system, the A4P four-point probe is designed to be maintenance-free and very easy to use. A variety of options are available for this system, including wide-range thermal testing, custom chucks for non-standard materials and 4-point probes customized for nearly any application.

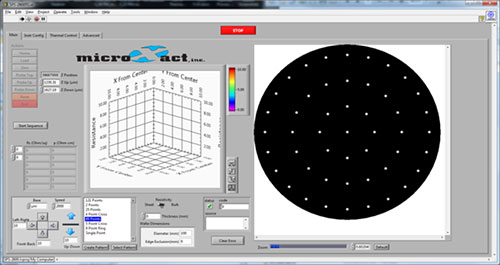

Resistivity Measurement Automation Software

The A4P-200-PLUS automation software permits semi-automated or fully automated testing with the resistivity mapping system. The Interface is designed to be simple yet powerful, allowing users to easily set up an automated testing procedure for nearly any kind of wafer structure. The LabView-based software is logically structured and allows for easy integration of the customer’s own test and measurement equipment. The software can be installed on any PC with Windows XP or higher operating system.

A4P 4-Point Probe Features

- Systems provide fast, accurate measurements and are very user friendly.

- Intuitive LabView-based open-source software offers a variety of data processing options as well as 2-D and 3-D mapping of results.

- Wide range of materials and structures that can be characterized.

- Wide resistivity measurement and sheet resistance ranges.

- Temperature range: from less than -60°C to over 300°C.

- Selectable 1-, 5-, 9-, 25-, 49-, or 121-point measurement modes as well as custom resistivity measurement modes.

- Adjustable vacuum chucks accommodate sample sizes ranging from 5mm to up to 300mm.

- Fast measurement mode in either ASTM, SEMI or simple output.

- Point & click or direct coordinate entry for wafer navigation.

- Compatible with Jandel probe heads.

- Vacuum or controlled environment version of the system is available for resistivity testing at extended temperature testing.

A4P 4-Point Probe Specifications

- A4P-200-TC

- A4P-200-TC

The following specifications are for a standard configuration. In most cases, each A4P 4-Point Probe system can be customized to exceed these values.

- Wafer Size

Up to 300mm

- Resistivity Measurement Range

1 mΩ/sq. to 500MΩ/sq.

- Measurement Equipment

Jandel RM3000 Test Unit

- Electronic Accuracy

0.3%

- Measurement Time

Better than 5s per point

- XYZ Resolution

<1.5μm

- Vacuum Chuck

Multi-zone vacuum

- Chuck Flatness

+/-13μm

- Chuck Breakdown Voltage

At least 500V

- Chuck Isolation

At least 1GW

- Compatible Probe Heads

Jandel probe heads

- Temperature Range

From -60°C to +310°C

- Feedthrough Terminals

BNC, Triax, or Banana Plug

- Automation software

LabView-based, Windows-compatible

- Output

Resistance & Resistivity, or Thickness Measurements